新聞中心

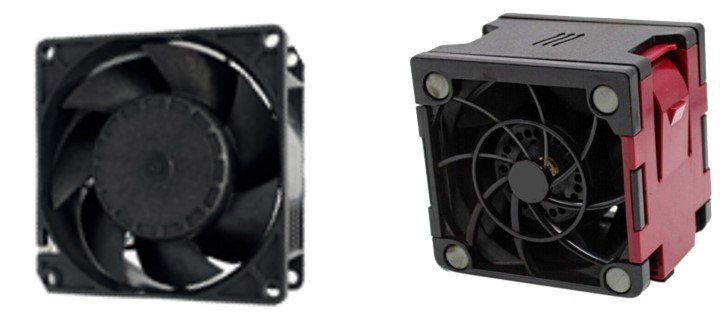

Introducing the MA853 ASIC: A Joint Effort for Superior Thermal Performance

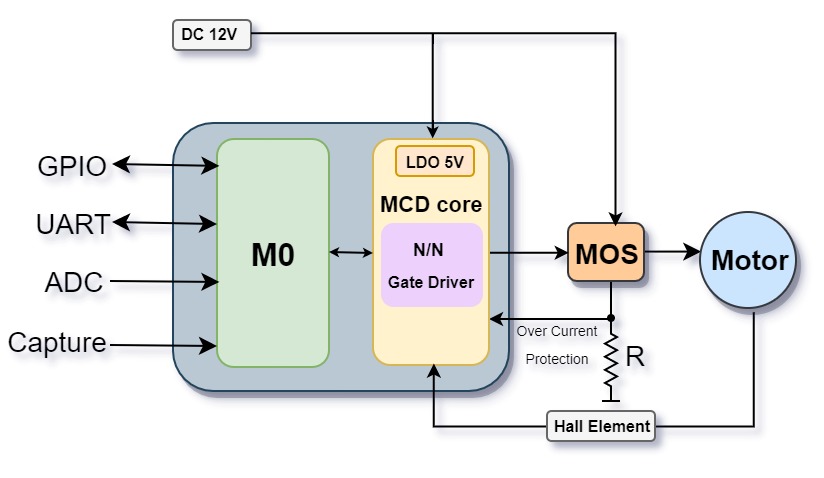

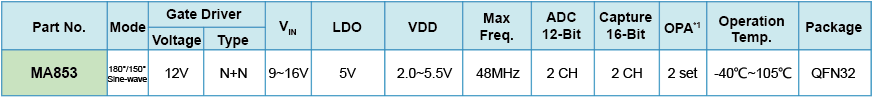

Megawin Technology’s server cooling fan solution adopts the 32-bit ASIC (MA853) as the main controller, featuring a dual-core architecture with Cortex®-M0 and an MCD motor control module of Toshiba Electronic to enable high-efficiency full-sine wave drive control. The MA853 integrates a high-performance gate driver capable of flexibly driving various external N-MOSFET components, offering both high integration and flexibility. It supports multi-point speed control and incorporates multiple protection mechanisms, effectively enhancing the fan’s operational stability and safety — meeting the stringent requirements of various high-efficiency cooling applications.

InPAC: The Key to Optimizing Motor Performance

Solution Features

● Built-in 5V LDO and N/N Gate Driver, fit into 25mm PCB like donuts

● Supports sensor-based full sine-wave control with only one Hall element or latch

● Voltage 12V, PWM carrier up to 93.7 kHz, and RPM up to 50,000 rpm

● Parameters can be set via software and program control can be performed through 4 Lines (COM port)

● Multi-points speed control for greater flexibility

● Open/Closed loop control, over-/under-voltage protection (FM/HW), over-temperature protection (HW), and over-current protection (HW)

Application Block Diagram

Feel free to contact one of our dealers, or request one of our sales representatives (sales@megawin.com.tw)。

Megawin Technology Co., Ltd.