Power tool market growth, Megawin Technology's Electric Drill Solution

Power tools are widely used in construction, manufacturing, woodworking, automotive repair, and home maintenance. Driven by the rise of DIY culture, increased construction and infrastructure activities, and advances in wireless tool technology, the global power tool market is estimated to reach US$33.44 billion in 2025. Projected to grow at a compound annual growth rate (CAGR) of approximately 6.8% from 2025 to 2037(according to a May 2025 report by Research Nester).

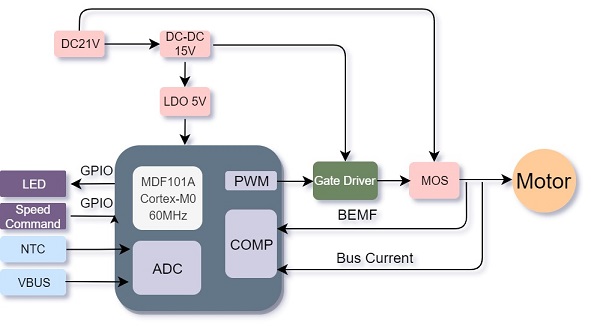

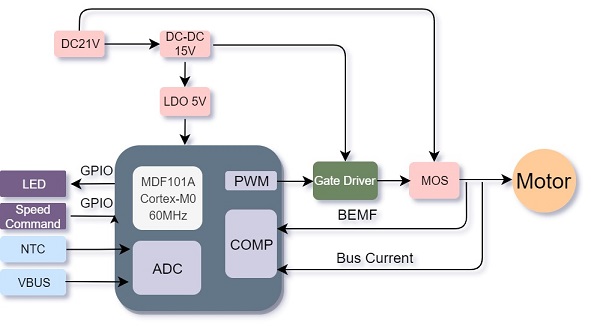

1. Solution Architecture Overview

Megawin Technology has unveiled an electric drill solution powered by the MDF101A chip, purpose-built for the next generation of power tool applications. Featuring a brushless motor drive architecture, it effectively addresses key challenges of traditional brushed motors—such as insufficient torque and rapid carbon brush wear—delivering greatly improved durability and operational stability.

Leveraging advanced sensorless square-wave control technology, the solution delivers high torque output and efficient operation, ensuring every drilling action is precise and powerful. With integrated multi-channel operational amplifiers and comparators, it significantly simplifies peripheral circuitry and reduces electromagnetic interference (EMI), enabling stable performance even in high-precision or harsh environments.

This solution is especially well-suited for a wide range of applications, including home renovation and maintenance, industrial manufacturing, and construction engineering—making it an ideal choice for professionals seeking smart, next-generation power tools.

2. Key Performance Advantages

1) Dynamic Torque Enhancement Technology

●Custom brushless motor paired with the MDF101A chip for coordinated control, delivering up to 120 N/m of peak torque—ideal for heavy-duty applications such as drilling into steel and boring through concrete.

●Self-adjusting load regulation: The chip integrates a 12-bit ADC for real-time current monitoring. Intelligent algorithms maintain a stable rotational speed, effectively preventing jamming or stalling during operation.

2) Sensorless Closed-Loop Control

●Utilizes back-EMF detection to determine rotor position without the need for Hall sensors, achieving precise commutation via onboard comparators.

●Adjustable hardware dead time (0~2 μs) prevents MOSFET shoot-through damage, improving system reliability by up to 40%.

3) Three Modes + Stepless Speed Control + Safety Features

●Three operating modes: Impact Mode, Drill Mode, and Screwdriver Mode.

●Features stepless speed control, high/low gear switching, and one-click forward/reverse rotation for flexible and safe operation.

Multiple Protection Mechanisms:

● Overcurrent protection (triggered at >90A)

● Over/undervoltage protection (Undervoltage protection at <12V, overvoltage protection at >28V)

● Locked-rotor protection (response time <100ms)

● MOSFET temperature monitoring (shutdown at >100°C)

● Phase loss protection (shutdown upon phase wire disconnection)

● Bias voltage detection protection (2.5V bias voltage detection)

● Auto power-off during inactivity (standby power consumption <0.1W)

3. Chip-level technology implementation

MDF101A Key Capabilities

● Core Architecture: Arm® Cortex®-M0 (60MHz)

● Motor Control Peripherals: 3-ch complementary PWM output + dead-time control, 12-bit ADC (1MSPS) current sampling

● Memory Expansion: 32KB Flash + 4KB RAM; Dedicated 3KB Flash for storing operational parameters

● Industrial Protection: 6KV ESD/EMC interference resistance design

● Real-time Control Optimization: Hardware divider accelerates torque and RPM calculation cycles (<2μs), ensuring RPM fluctuation rate <5% during high-speed drilling

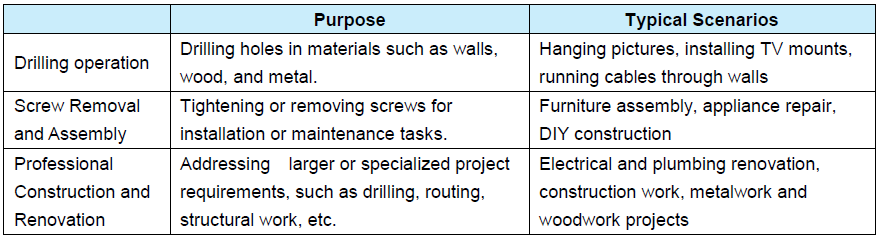

4. Typical Application Scenarios

5. Core Value Proposition

1. Cutting-Edge Algorithms

● Sensorless square-wave comparator control enables zero-speed high-torque startup with safety and reliability

2. Extended Lifespan

● Brushless motor lifespan >10,000 hours (traditional brushed motors <2,000 hours)

● Chip-level protection reduces circuit board repair rates by 60%

3. Energy Efficiency Breakthrough

● Intelligent commutation algorithm minimizes copper losses, achieving 92% energy conversion efficiency

● Sleep mode extends battery standby time to 18 months

6.Application Block Diagram

7. Conclusion

Megawin Technology’s MDF101A drill solution features an industrial-grade chip at its core, utilizing sensorless square-wave control technology to deliver an ultra-high torque output of up to 120N/m. Featuring four built-in intelligent speed adjustment modes, it flexibly covers diverse applications ranging from precision electronic installation to concrete demolition. The solution simultaneously enhances overload protection and EMC interference resistance, delivering a triple-support technology foundation of “high torque, long lifespan, and low failure rate” for professional-grade power tools.

*If you are interested in the Power Tool (Electric Tool) solution or need further information, please visit the website of Megawin Technology:

Feel free to contact one of our dealers, or request one of our sales representatives (sales@megawin.com.tw)。

Megawin Technology Co., Ltd.